Nový MRM 120 C KOMPAKT BETON SANTRALİ - 120 C CENTRALE À BÉTON COMPCAKTE

cena na vyžádání

Betonárna

2023

120 m3/h

Turecko

Nový MRM 120 C KOMPAKT BETON SANTRALİ - 120 C CENTRALE À BÉTON COMPCAKTE

cena na vyžádání

Betonárna

2023

120 m3/h

Turecko

Inzerát Nový betonárna Semix Stationary 130 STATIONARY CONCRETE BATCHING PLANTS 130m³/h byl prodán a není zahrnut do vyhledávání!

Podobné inzeráty

Nový MRM 120 C KOMPAKT BETON SANTRALİ - 120 C CENTRALE À BÉTON COMPCAKTE

cena na vyžádání

Betonárna

2023

120 m3/h

Turecko

Nový MRM 120 C KOMPAKT BETON SANTRALİ - 120 C CENTRALE À BÉTON COMPCAKTE

cena na vyžádání

Betonárna

2023

120 m3/h

Turecko

Nový Pi Makina

cena na vyžádání

Betonárna

0/2023

60 m3/h

Turecko, Ankara

Nový Pi Makina

cena na vyžádání

Betonárna

0/2023

60 m3/h

Turecko, Ankara

Nový Pi Makina 100 BTS STATIONARY CONCRETE BATCHING PLANTS

cena na vyžádání

Betonárna

2023

100 m3/h

Turecko, Ankara

Nový Pi Makina 100 BTS STATIONARY CONCRETE BATCHING PLANTS

cena na vyžádání

Betonárna

2023

100 m3/h

Turecko, Ankara

Nový Pi Makina 60 m3/h MOBILE - TWIN SHAFT MIXER CONCRETE PLANT

cena na vyžádání

Betonárna

2023

60 m3/h

Turecko, Ankara

Nový Pi Makina 60 m3/h MOBILE - TWIN SHAFT MIXER CONCRETE PLANT

cena na vyžádání

Betonárna

2023

60 m3/h

Turecko, Ankara

Nový Asur Makina STN 160 TWN

cena na vyžádání

Betonárna

01/2023

160 m3/h

Turecko

Nový Asur Makina STN 160 TWN

cena na vyžádání

Betonárna

01/2023

160 m3/h

Turecko

Prodané

1/7

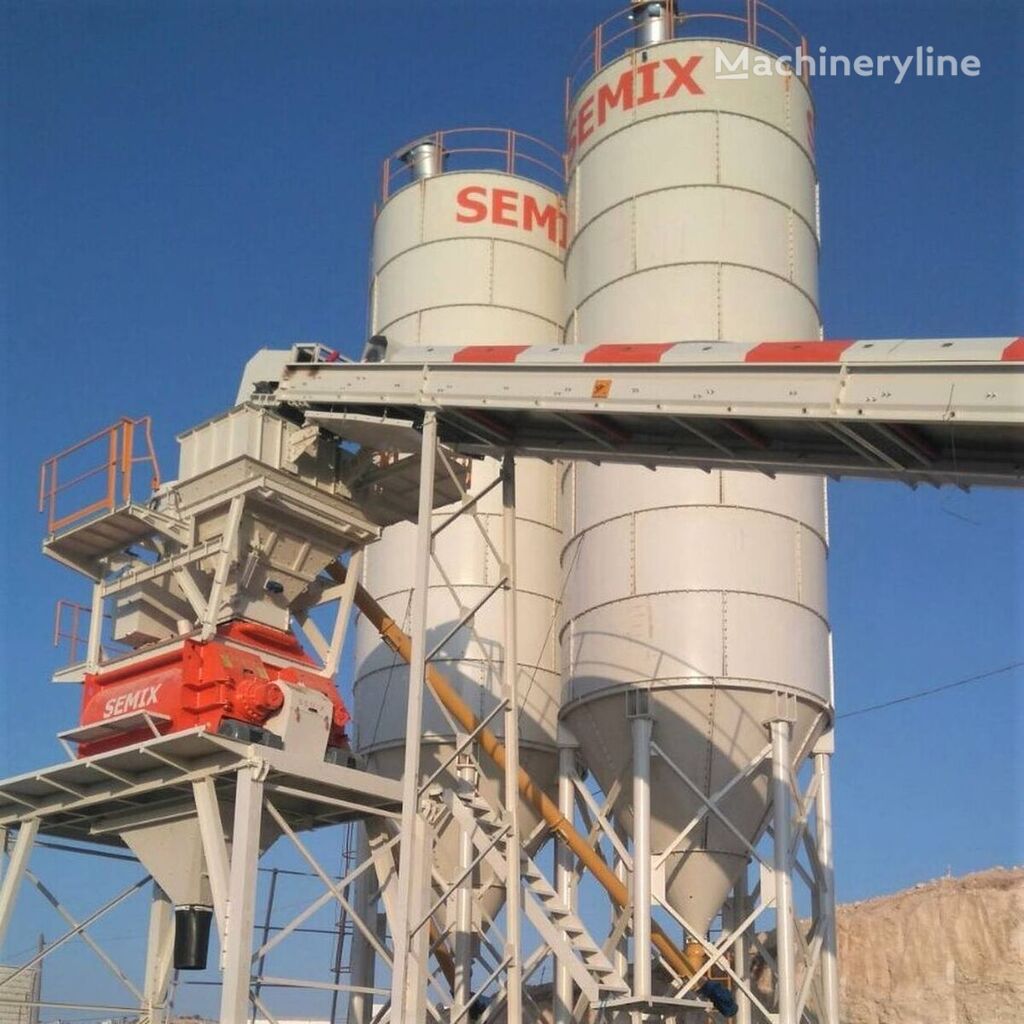

Značka:

Semix

Model:

Stationary 130 STATIONARY CONCRETE BATCHING PLANTS 130m³/h

Typ:

betonárna

Rok výroby:

2023

Lokalizace:

Turecko ANKARA

Turecko ANKARA

Datum zanesení:

déle než jeden 1 měsíc

Machineryline ID:

KA24525

Stav

Stav:

nový

All SEMIX Aggregate Storage hoppers are bent trapezoidal shape for having an extra strength. The robust steel structure maintains long-life performance. Aggregates are weighed in the weighing conveyor which transfers aggregates to the transfer conveyor. Having two separate conveyors providing accuracy in weighing and performance for reaching higher Concrete outputs.

In SEMIX Stationary Concrete Batching Plants, above the mixer, the aggregate waiting hopper is located. This hopper holds the aggregate ready for the next batch and this provides time efficiency for the batching processes.

All SEMIX Concrete Batching Plants are being controlled by a SCADA system with a Schneider PLC integrated. Users can follow all used materials and integrate their CRM system. SEMIX's engineering team can intervene in the Automation system online to provide service.